Automation has advanced manufacturing to unprecedented levels like never seen before. However, its impact goes beyond simply speeding up production. What many businesses fail to recognize is that they can extract valuable insights about their products and customers automatically and directly apply that analysis to their factory operations.

In the age of the Internet, everything is interconnected, including businesses. By integrating smart manufacturing processes and Industrial Internet of Things (IIoT) technology with the cloud, businesses can access critical data that can optimize operations, improve scalability, and even drive sales growth.

What is smart manufacturing?

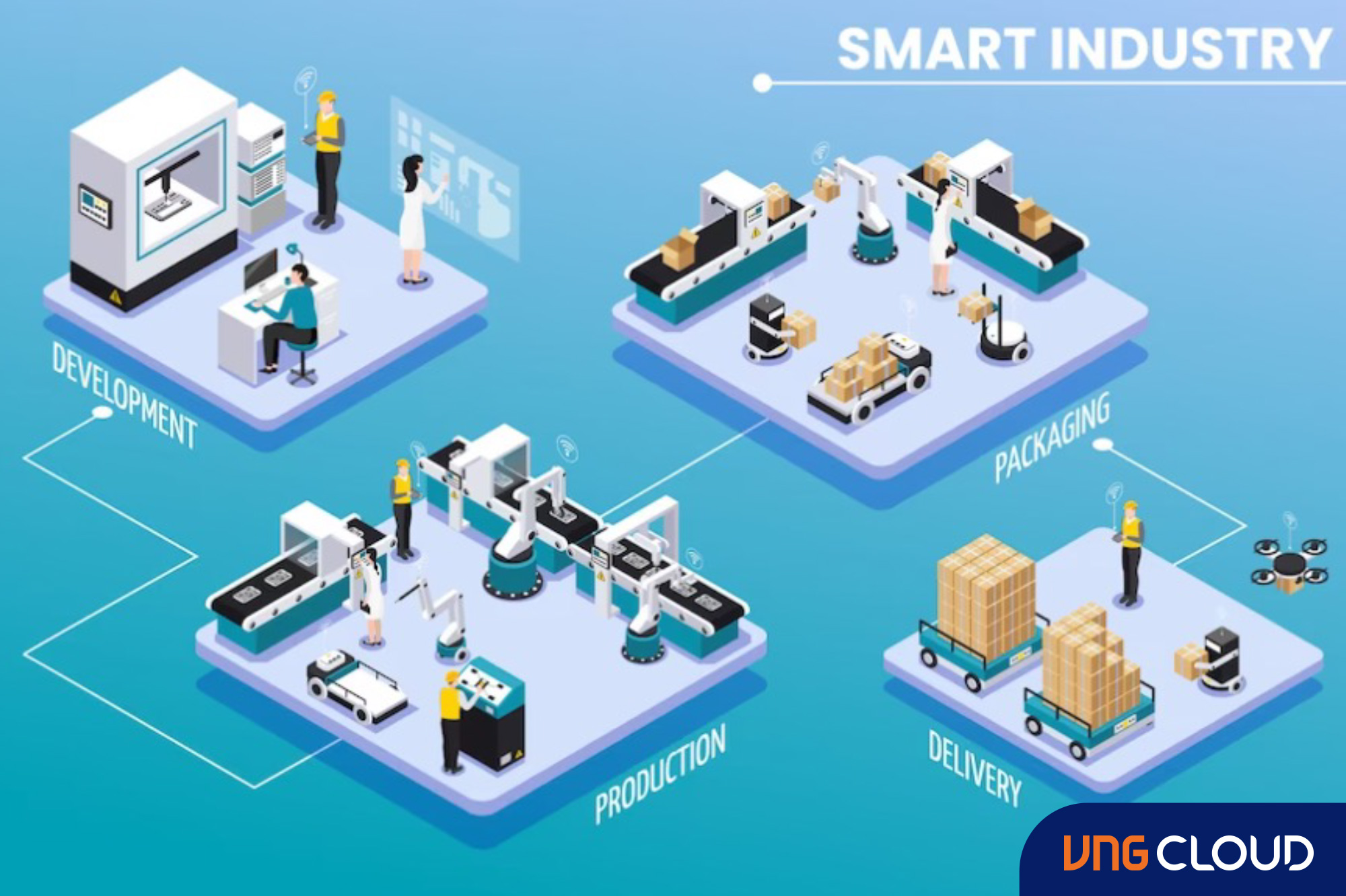

Smart manufacturing leverages digital information technology and computer-integrated manufacturing processes to automate production across various industries. These advanced techniques are applied in the creation of a wide range of products, from cutting-edge robotics equipment to everyday consumer goods. Smart factories, or any other facilities that adopt these methods, are often fully automated, requiring minimal human intervention.

The adoption of a smart manufacturing ecosystem provides businesses with enhanced flexibility, enabling rapid adjustments in production levels, optimized supply chain logistics, and improved overall efficiency. Additionally, with fewer workers present on the technologically advanced factory floors, these businesses can effectively reduce workplace injuries and hazards compared to traditional manufacturing environments.

The foundation of smart manufacturing lies in the utilization of sensors and devices that are part of the Industrial Internet of Things (IIoT). These interconnected technologies play a crucial role in integrating data and enabling seamless communication within the manufacturing ecosystem.

Then, what is Industrial Internet of Things (IIoT)?

In recent times, the Internet of Things (IoT) has gained widespread recognition, with a surge in the usage of IoT devices. Smartwatches, personal fitness devices, and home automation systems have become common, constantly transmitting and receiving information, ensuring round-the-clock connectivity. These devices enable us to stay updated with personal communications, monitor our health and well-being, and maintain energy-efficient and secure homes.

Expanding beyond personal devices, the Industrial Internet of Things (IIoT) plays a pivotal role in automating and improving various industrial operations. According to GE, IIoT devices have the ability to "monitor, collect, exchange, analyze, and deliver valuable new insights," facilitating smarter and faster decision-making for industrial companies. The IIoT has found applications in sectors such as manufacturing, logistics, oil and gas, energy utilities, mining, transportation, aviation, and more, connecting users with facilities through this interconnected network.

Of these sectors, manufacturing stands out as the largest market for IIoT. In 2016, manufacturing operations accounted for $102.5 billion of the total $178 billion IoT market, according to analyst firm IDC. According to Statista, it’s also estimated to have revenues reaching more than $3 trillion in 2030.

The Industrial Internet of Things brings several advantages to manufacturing production lines. Executives, as per research conducted by Morgan Stanley, have reported improved operational efficiency, increased productivity, reduced downtime, and the creation of new business opportunities through enhanced efficiency and cost-effectiveness. However, the benefits of connectivity extend beyond these achievements.

One of the main challenges faced when implementing IoT in manufacturing and other sectors is the large volume of data generated. Businesses require a reliable storage and access solution for this data, which is why they often turn to the cloud. IIoT and cloud computing are complementary technologies, and it is essential for manufacturers to thoroughly research the features and capabilities of any cloud service to ensure compatibility with their specific IIoT operations.

What advantages do manufacturers gain by integrating IIoT with the cloud?

As mentioned above, IIoT and Cloud computing are complementary, so adopting the cloud offers manufacturers a multitude of operational and competitive benefits.

1. Lower expenses and improved profit margins

Evidently, applying cloud technology can save enterprises cost on IT operation. Alos, the pay-as-you-go model of the cloud allows businesses to pay for the resources they actually utilize. This capability enables them to reduce or eliminate expenses associated with operating an on-premise data center. By avoiding the significant costs of maintaining the on-premise data centers, businesses can achieve higher profit margins by moving to cloud.

2. Enhanced versatility and real-time data monitoring

Through cloud integration, managers and employees gain the ability to remotely monitor machinery from any location, including off-site premises. In smart factories, technicians can receive immediate notifications regarding issues on the automation assembly line and be alerted about the maintenance requirements of factory equipment. By connecting IIoT to the cloud, businesses benefit from increased flexibility, enabling employees to work effectively from virtually anywhere across the globe.

3. Enhanced scalability in discrete manufacturing

The combination of IIoT and cloud applications offers significant improvements in manufacturing operations, regardless of scale. Discrete manufacturing, which involves producing products with high complexity in low volumes or high volumes with lower complexity, can benefit greatly from IIoT. The cloud can enhance IIoT capabilities, effectively supporting manufacturers in scaling their production levels up or down as needed, thereby ensuring optimal flexibility and efficiency in their operations.

4. Enhanced customer insights and targeted promotions

Smart factories play a crucial role in empowering companies to make informed decisions based on valuable customer information. By leveraging IIoT data with cloud solutions, businesses can gain insights into their customers' purchasing patterns, allowing them to develop specialized and targeted offerings that align with their customers' preferences and needs. This integration of customer insights and IIoT data enables businesses to deliver more personalized promotions, fostering stronger customer relationships and driving sales growth.

5. More competitive product development and logistics

By integrating IIoT with cloud computing, manufacturing facilities gain access to real-time product usage data and customer feedback. This enables them to address quality issues promptly on the factory floor, reducing waste and mitigating costs. Leveraging machine learning on cloud-stored data provides businesses with actionable insights for future product development, leading to increased sales and improved customer satisfaction. Moreover, this approach brings businesses closer to an on-demand model, allowing customers to place unique orders without the additional wait time for product delivery.

The integration of IIoT operations into the cloud is a multifaceted undertaking that requires careful consideration and planning. While it may seem daunting, by adopting a strategic approach and leveraging the expertise of professionals, manufacturers have the opportunity to tackle these challenges head-on and successfully navigate the path towards seamless integration.